Numerical Modeling of Toe-to-Heel Air Injection and Its Catalytic Variant (CAPRI) under Varying Steam Conditions

世界各地都有巨大的重油储量,可以进行能源密集型开采。提高开采过程的能源效率和开发新的清洁开采方法对于从传统化石燃料使用向净零排放转型至关重要。原位燃烧(ISC)是一种使用较少的技术,从THAI火驱和原位催化改质(CAPRI)是传统ISC的专门新版本。它们使用水平生产井,在CAPRI的情况下使用催化剂。本文旨在研究注入蒸汽对THAI和CAPRI工艺的影响,以实现原位HO重油组分改质,用于弥合现有实验室研究与未知商业潜力之间的差距。

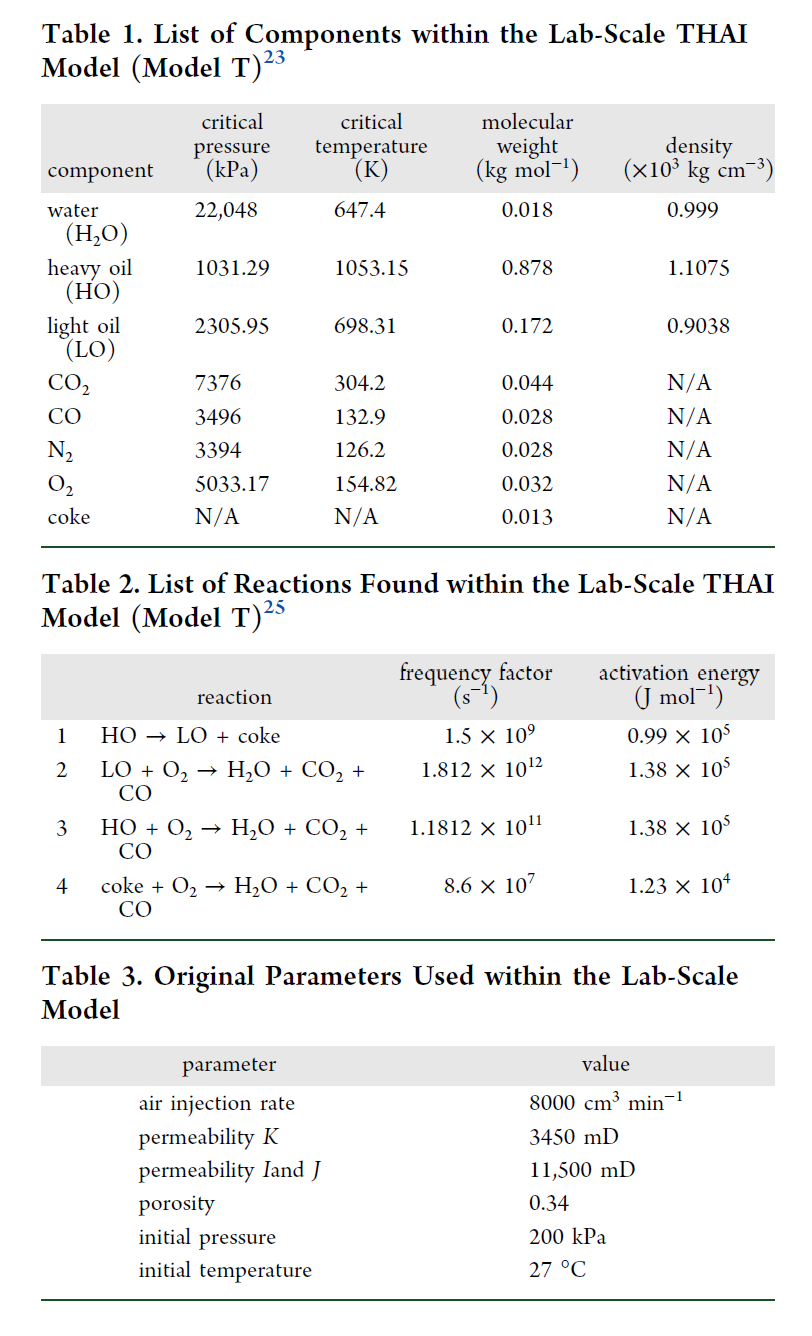

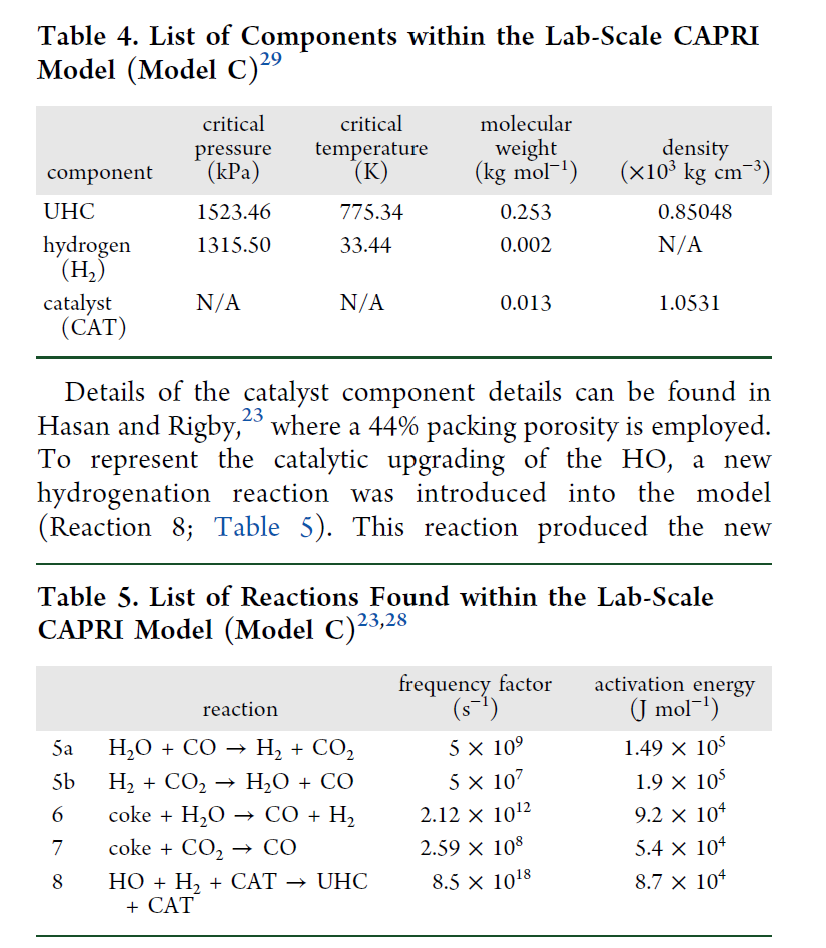

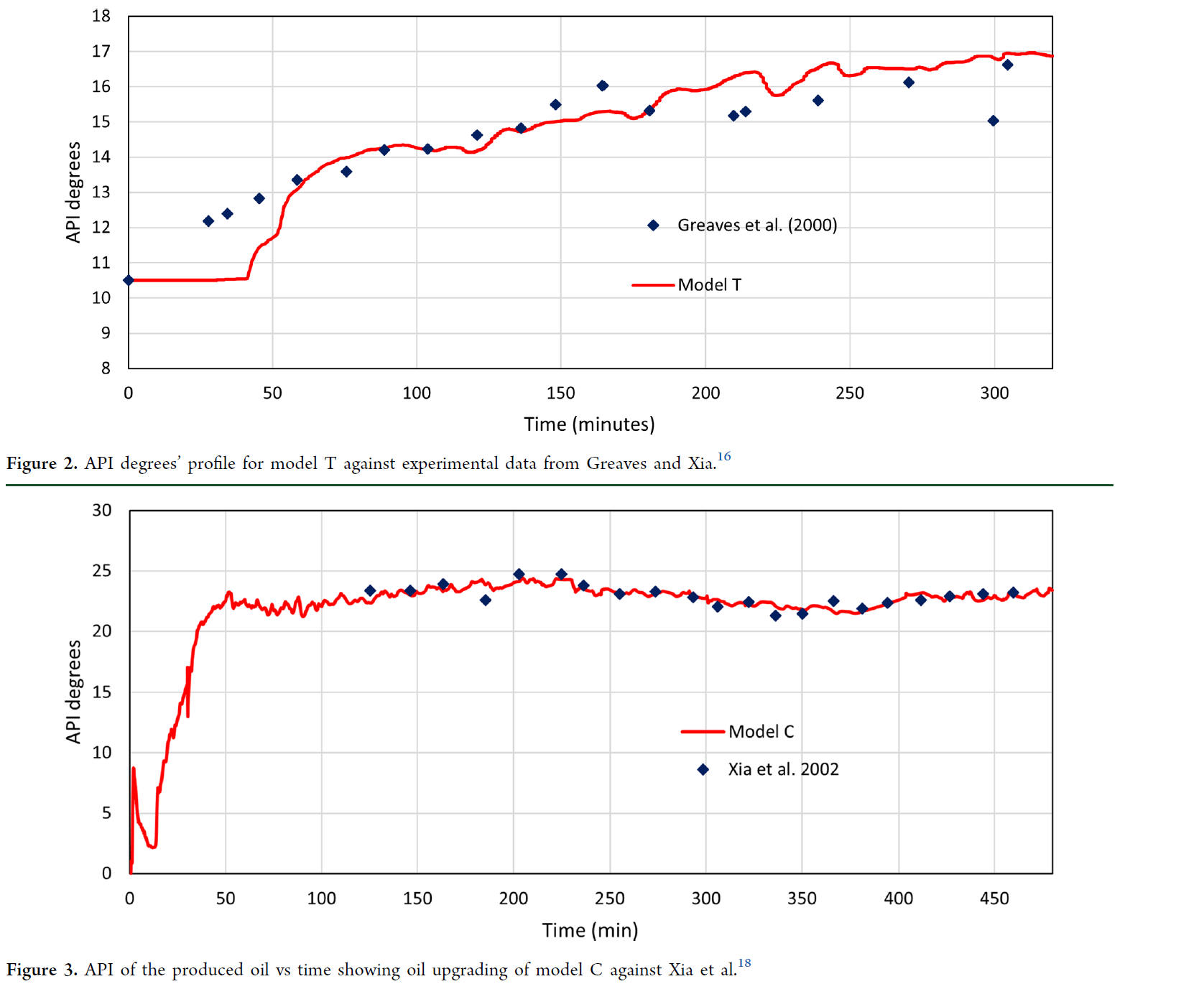

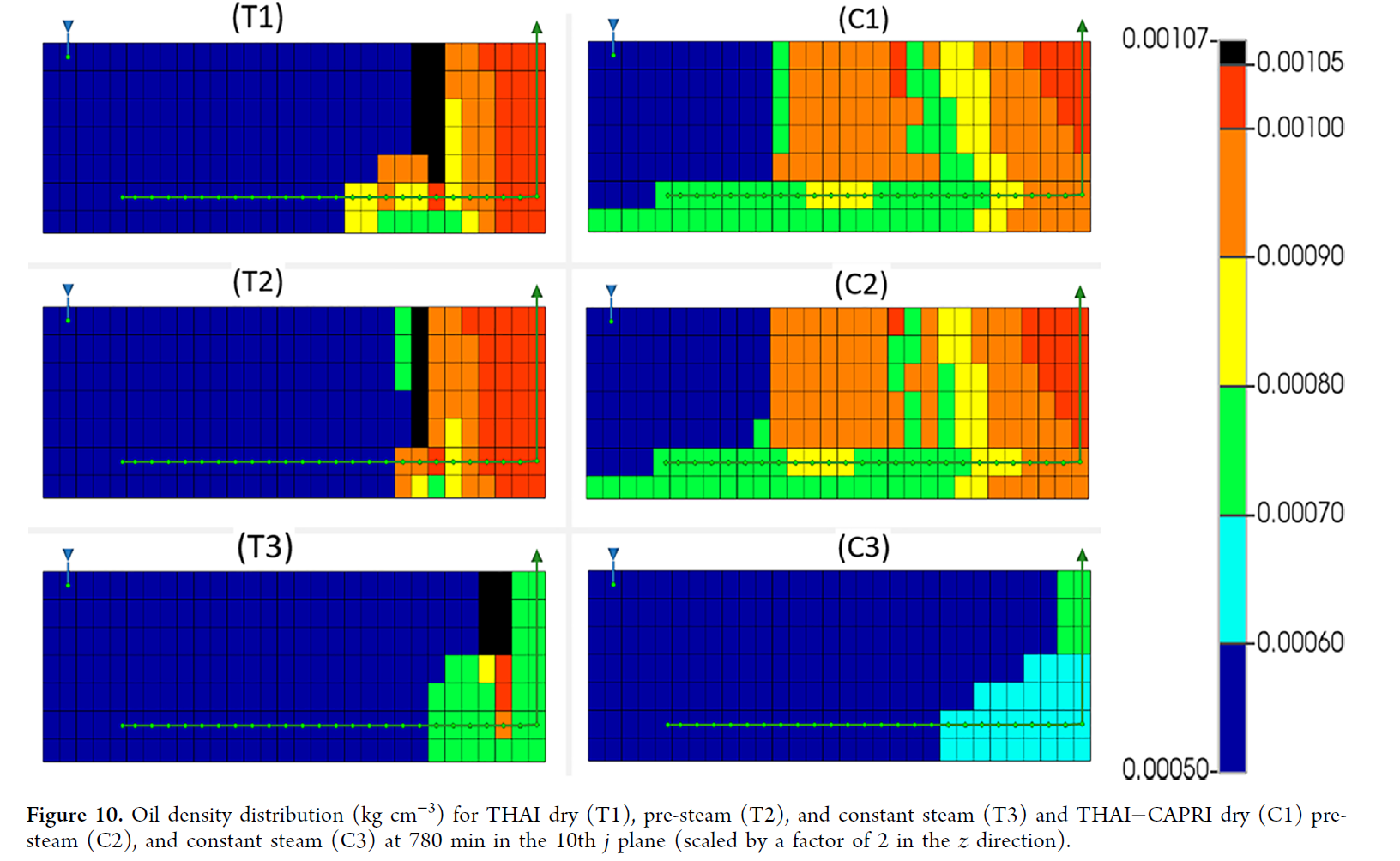

本研究还提出了一种使用CMG STARS对THAI–CAPRI过程模拟的新方法,提出了一个原位制氢反应方案。THAI和CAPRI实验规模模型在三种条件下运行:干燥、预蒸汽和恒定蒸汽。从储层API重度10.5开始,THAI过程达到了~16点的平均API,表明使用蒸汽注入后API产量没有增加。由于高温氧化占主导地位的环境,在持续的蒸汽注入过程中,API输出降低了约0.7个点。这降低了用于热裂化的反应物的可用性。CAPRI试运行达到了20.40API,并在预蒸(~21.17分)和持续蒸(~222.13分)方面实现了API输出的增加。讨论了这种升级增加的机理,与热裂化相反,催化升级被证明是升级增加的原因。这两种工艺在干燥和预蒸运行期间产生相似的累积油量(~3150 cm3),在THAI期间持续注入蒸汽时仅增加到~3300 cm3,CAPRI则增加到3500 cm3。

Abstract

There are huge reserves of heavy oil (HO) throughout the world that can be energy-intensive to recover. Improving the energy efficiency of the recovery process and developing novel methods of cleaner recovery will be essential for the transition from traditional fossil fuel usage to net-zero. In situ combustion (ISC) is a less used technique, with toe-to-heel air injection (THAI) and catalytic processing in situ (CAPRI) being specialized novel versions of traditional ISC. They utilize a horizontal producing well and in the case of CAPRI, a catalyst. This paper aims to investigate the impact that injected steam has on both the THAI and CAPRI processes for the purpose of in situ HO upgrading and will help to bridge the gap between the extant laboratory research and the unknown commercial potential.

This study also presents a novel method for modeling the THAI–CAPRI method using CMG STARS, proposing an in situ hydrogen production reaction scheme. THAI and CAPRI experimental-scale models were run under three conditions: dry, pre-steam, and constant steam. Starting from a reservoir American Petroleum Institute (API) of 10.5°, THAI reached an average API of ∼16 points, showing no increase in the API output with the use of steam injection. A decreased API output by ∼0.7 points during constant steam injection was achieved due to a high-temperature oxidation-dominant environment. This decreases the reactant availability for thermal cracking. The CAPRI dry run reached an API of 20.40 points and achieved an increased API output for both pre-steaming (∼21.17 points) and constant steaming (∼22.13 points). The mechanics for this increased upgrading were discussed, and catalytic upgrading, as opposed to thermal cracking, was shown to be the reason for the increased upgrading. Both processes produce similar cumulative oil (∼3150 cm3) during dry and pre-steamed runs, only increasing to ∼3300 cm3 with the constant steam injection during THAI and 3500 cm3 for CAPRI.