Study of Gas Production from Shale Reservoirs with Multi-Stage Hydraulic Fracturing Horizontal Well Considering Multiple Transport Mechanisms

Abstract

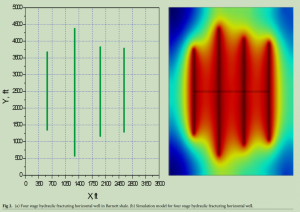

Development of unconventional shale gas reservoirs (SGRs) has been boosted by the advancements in two key technologies: horizontal drilling and multi-stage hydraulic fracturing. A large number of multi-stage fractured horizontal wells (MsFHW) have been drilled to enhance reservoir production performance. Gas flow in SGRs is a multi-mechanism process, including: desorption, diffusion, and non-Darcy flow. The productivity of the SGRs with MsFHW is influenced by both reservoir conditions and hydraulic fracture properties. However, rare simulation work has been conducted for multi-stage hydraulic fractured SGRs. Most of them use well testing methods, which have too many unrealistic simplifications and assumptions. Also, no systematical work has been conducted considering all reasonable transport mechanisms. And there are very few works on sensitivity studies of uncertain parameters using real parameter ranges. Hence, a detailed and systematic study of reservoir simulation with MsFHW is still necessary. In this paper, a dual porosity model was constructed to estimate the effect of parameters on shale gas production with MsFHW.

The simulation model was verified with the available field data from the Barnett Shale. The following mechanisms have been considered in this model: viscous flow, slip flow, Knudsen diffusion, and gas desorption. Langmuir isotherm was used to simulate the gas desorption process. Sensitivity analysis on SGRs’ production performance with MsFHW has been conducted. Parameters influencing shale gas production were classified into two categories: reservoir parameters including matrix permeability, matrix porosity; and hydraulic fracture parameters including hydraulic fracture spacing, and fracture half-length. Typical ranges of matrix parameters have been reviewed. Sensitivity analysis have been conducted to analyze the effect of the above factors on the production performance of SGRs. Through comparison, it can be found that hydraulic fracture parameters are more sensitive compared with reservoir parameters. And reservoirs parameters mainly affect the later production history matching process. Also, it can contribute to the design and optimization of hydraulic fracture treatment design in unconventional SGRs. period. However, the hydraulic fracture parameters have a significant effect on gas production from the early period. The results of this study can be used to improve the efficiency of history matching process. Also, it can contribute to the design and optimization of hydraulic fracture treatment design in unconventional SGRs.