PERFORMANCE EVALUATION OF AN ENHANCED CYCLIC SOLVENT PROCESS (ECSP) FOR THIN HEAVY OIL RESERVOIRS

加拿大稠油油藏中的原油非常粘稠,且含有薄层,采用现有技术只能采出8-9%的原始地质储量(OOIP)。研究发现,蒸汽吞吐和蒸汽辅助重力驱油(SAGD)和溶剂萃取(VAPEX)通常无法开采此类薄储层中的稠油。实验表明,强化循环溶剂法(ECSP)可以通过循环使用甲烷(CH4)和丙烷(C3H8)作为两个独立的段塞来提高薄地层中的稠油采收率。此前,还没有进行全面的数值模拟来评估ECSP在实验室和现场效果。

对溶剂-重油系统进行了压力-体积-温度(PVT)进行试验研究。然后,使用CMG WinProp模块模拟PVT物性。每个试验温度下的CH4-C3H8-重油混合物,重油的膨胀系数保持在相对较高的值,而测得的饱和压力也为较高的值。调整后的Peng-Robinson状态方程(PR EOS)(1978)模型可用于再现饱和压力和溶胀因子,平均相对误差分别为3.68%和3.76%,而改进的粘度模型可预测溶剂-重油体系的粘度,平均相对误差为10.74%。

采用数值技术进行实验室尺度上ECSP剖面历史拟合,同时研究了分子扩散、分散和泡沫油对最终采收率的影响。最后,利用正交设计方法对操作参数进行了优化。对于每个单独的ECSP实验,实验结果和数值结果之间存一致性良好。

ABSTRACT

Canada’s energy future depends on heavy oil resources, which are mainly located in Western Canada, i.e., Saskatchewan and Alberta, and account for almost half of the total world heavy oil reserves. At present, only 8-9% of the original oil in place (OOIP) can be recovered in such heavy oil reservoirs with the current available technology because the oil is very viscous and contained in thin formations. It has been found that cyclic steam stimulation and steam-assisted gravity drainage (SAGD) and vapour extraction (VAPEX) often do not work for recovering heavy oil in such thin reservoirs. The enhanced cyclic solvent process (ECSP) experimentally shows its potential to increase heavy oil recovery in such thin formations by using methane (CH4) and propane (C3H8) as two separate slugs in a cyclic manner. So far, no comprehensive numerical simulation has been conducted to evaluate the performance of the ECSP in the laboratory- and fieldscale.

Pressure-volume-temperature (PVT) tests have been performed for the solvent(s)- heavy oil systems. Then, the PVT properties are simulated by using the CMG WinProp module. For the CH4-C3H8-heavy oil mixture, the swelling factor of heavy oil maintains at a relatively high value for each test temperature, while the measured saturation pressures are also found to have high values. The tuned Peng-Robinson equation of state (PR EOS) (1978) model can be used to reproduce the saturation pressures and swelling factors with an average relative error of 3.68% and 3.76%, respectively, while the modified viscosity model is able to predict the viscosity of solvent(s)-heavy oil systems with an average relative error of 10.74%.

Numerical techniques are developed to history match the ECSP profile in the laboratory scale, while efforts have been made to examine the effects of molecular diffusion, dispersion, and foamy oil behaviour on the ultimate oil recovery. Finally, the operational parameters are optimized by using the orthogonal design method. There exists a good agreement between the experimental and numerical results for each individual ECSP test. As for the diffusion coefficient, a minor impact on the oil recovery is observed while the dispersion coefficient imposes a strong impact. The reaction frequency factor (RFF) for gas exsolution from bubble to gas phase almost shows no influence on the simulated oil recovery. In comparison, the RFFs for gas dissolution and exsolution from oil phase to bubble affect the oil recovery to a larger extent. The injection pressure of CH4 and minimum production pressure are found to be the most sensitive parameters.

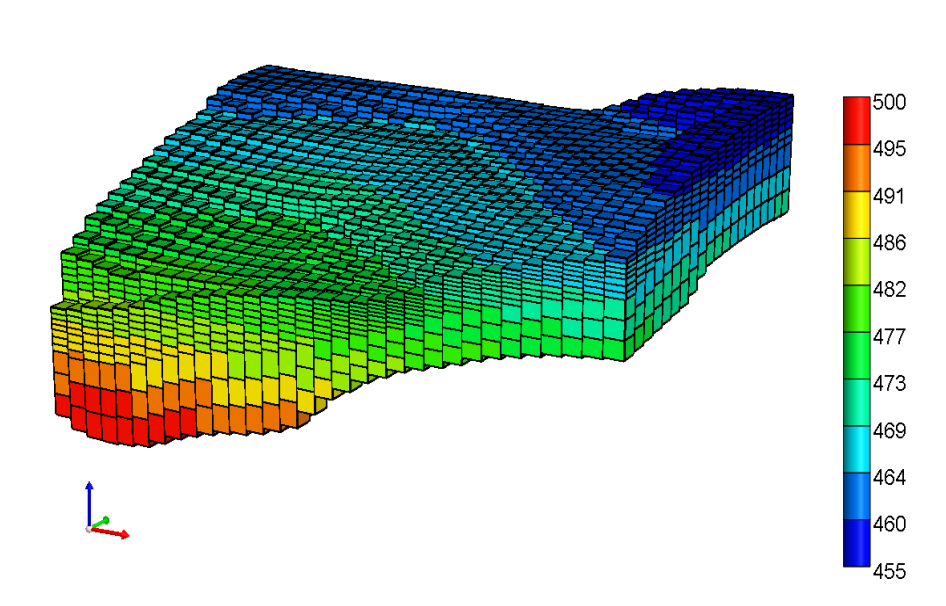

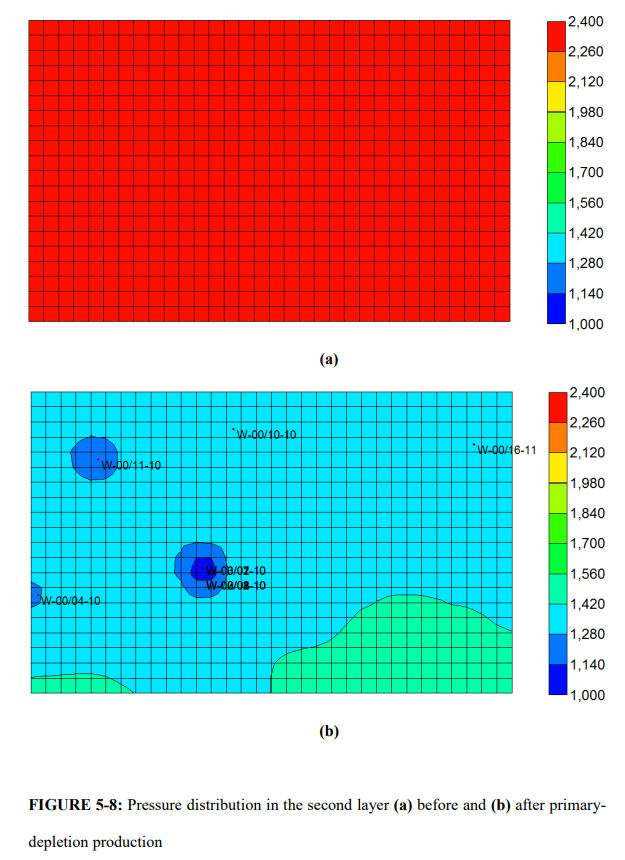

The field-scale simulation is conducted to evaluate the ECSP performance in the Pelican oilfield. Subsequently, the orthogonal design method is applied to optimize the operational parameters. Finally, these optimized operational parameters are selected to predict the production performance. There exists a good agreement between the simulated production profiles and the observed field data. The minimum well bottomhole pressure is found to be the most sensitive parameter while the injection time of CH4 and C3H8 as well as soaking time are also subject to relatively large sensitivities. As for the ECSP performance, the cumulative oil production increases quickly with time once theECSP is initiated, and then its increasing rate slows down slightly after two years of production. After ECSP treatment, the oil saturation decreases due to good oil production near the wellbore and the exsolution of solution gas from heavy oil.