Foam Application in Fractured Carbonate Reservoirs: A Simulation Study

CMG软件的应用情况

-

流体模型构建:使用CMG WinPropTM软件创建CO2-油和CO2-盐水混合物的组成和性质。

-

模拟实验设计:将流体模型整合到CMG-GEMTM组成的和非传统储层模拟器中,以重现本研究中进行的泡沫注入和CO2-WAG驱替测试。

-

结果预测与分析:通过模拟实验结果,预测泡沫注入在高压和高温条件下的表现,并与实验结果进行对比分析,验证模型的准确性。

作者单位

-

Ahmed Zoeir, Mohammad Chahardowli, Mohammad Simjoo 伊朗大不里士沙罕理工大学石油与天然气工程学院

Abstract

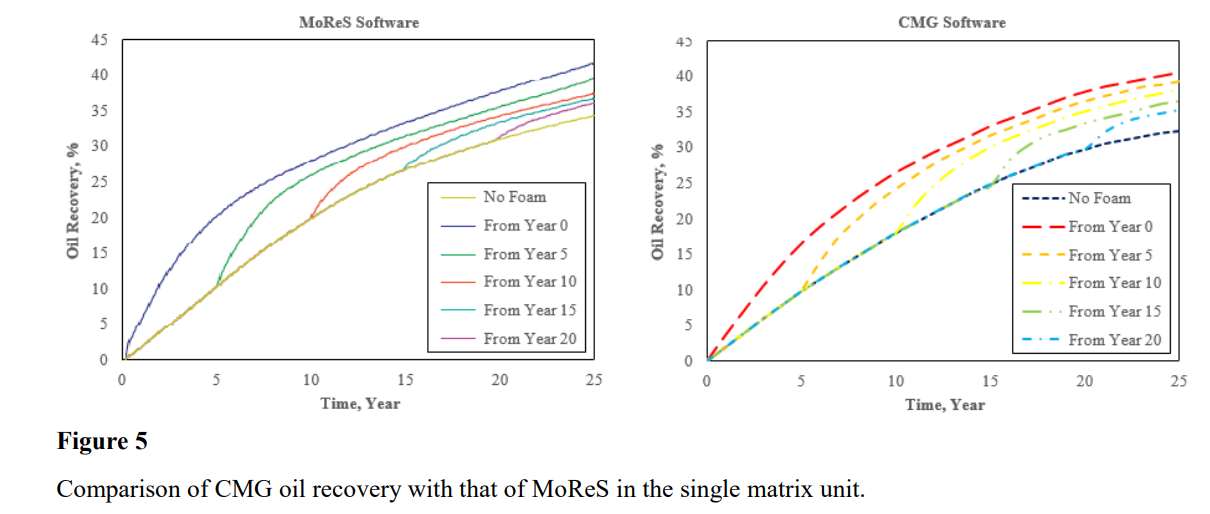

Fractured carbonate reservoirs account for 25% of world’s total oil resources and for 90% of Iranian oil reserves. Since calcite and dolomite minerals are oil wet, gas oil gravity drainage (GOGD) is known as the most influencing production mechanism. The most important issue within gas injection into fractured media is the channeling problem which makes the efficiency of gas injection process extremely low. As a solution, foam is used to change the mobility ratio, to increase volumetric sweep efficiency, and to overcome the fingering problem. In this work, we inspected three main influencing mechanisms that affect oil extraction from matrix, namely foam/oil gravity drainage, viscous pressure drop due to foam flow in fractures, and foaming agent diffusion from fractures into the matrixes. Foam injection simulations were performed using CMG STARS 2015, on a single matrix unit model and on some vertical cross section models. A number of sensitivity analyses were performed on foam strength, injection rate, fracture and matrix properties, matrix heights, and the initial oil saturation within matrixes. The results show that the roles of the mass transfer of the foaming agent and viscous pressure drop are significant, especially when matrix average heights are small. Moreover, the mechanism for viscous pressure drop remains unchanged, which continues to aid oil extraction from matrixes while the other two mechanisms weaken with time.

Keywords: Foam, Fractured Reservoir, Gravity Drainage, Gas Invaded Zone, CMG STARS