Pressure History Matching for CO2 Storage in Saline Aquifers: Case Study for Citronelle Dome

碳捕集和储存(CCS)项目需要进行监测和验证方案以确保储存安全运行。在不同的验证技术中,储层模拟和建模已经被证明是预测地下储存行为和因此量化与二氧化碳储存过程相关风险的强大工具。

储层模拟模型的可靠性高度依赖于模拟结果能够准确地代表实际现场测量数据。本文介绍了一种旨在历史拟合二氧化碳储层模拟模型的工作流程。在本研究中,考虑了位于美国阿拉巴马州莫宁县Citronelle圆顶的盐水储层进行历史拟合。

该项目是美国能源部(DOE)和一些工业合作伙伴进行的一项二氧化碳储存研究计划的一部分,旨在证明从现有的燃煤发电厂捕集的二氧化碳以商业规模进行储存的可行性。使用商业软件(CMG-GEM)建立了一个用于将二氧化碳注入Citronelle盐水含水层的储层模拟模型。将二氧化碳注入速率的现场测量结果作为模型的操作约束。

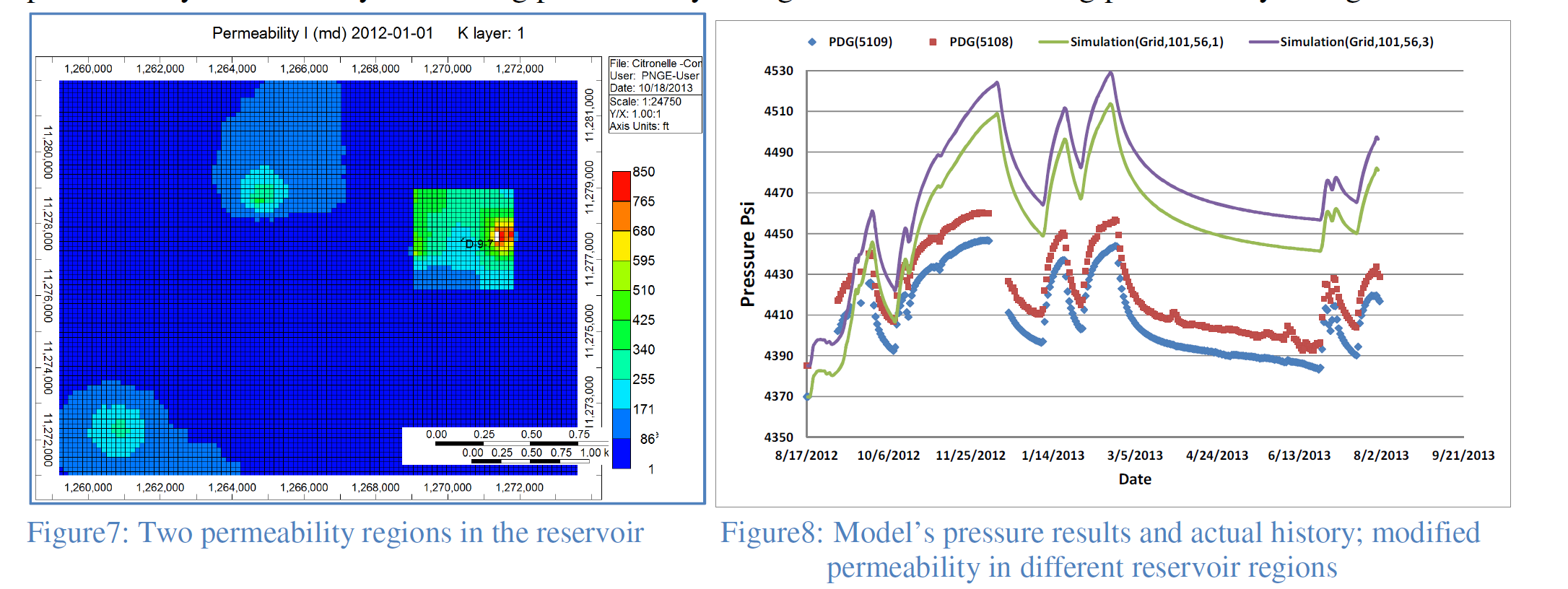

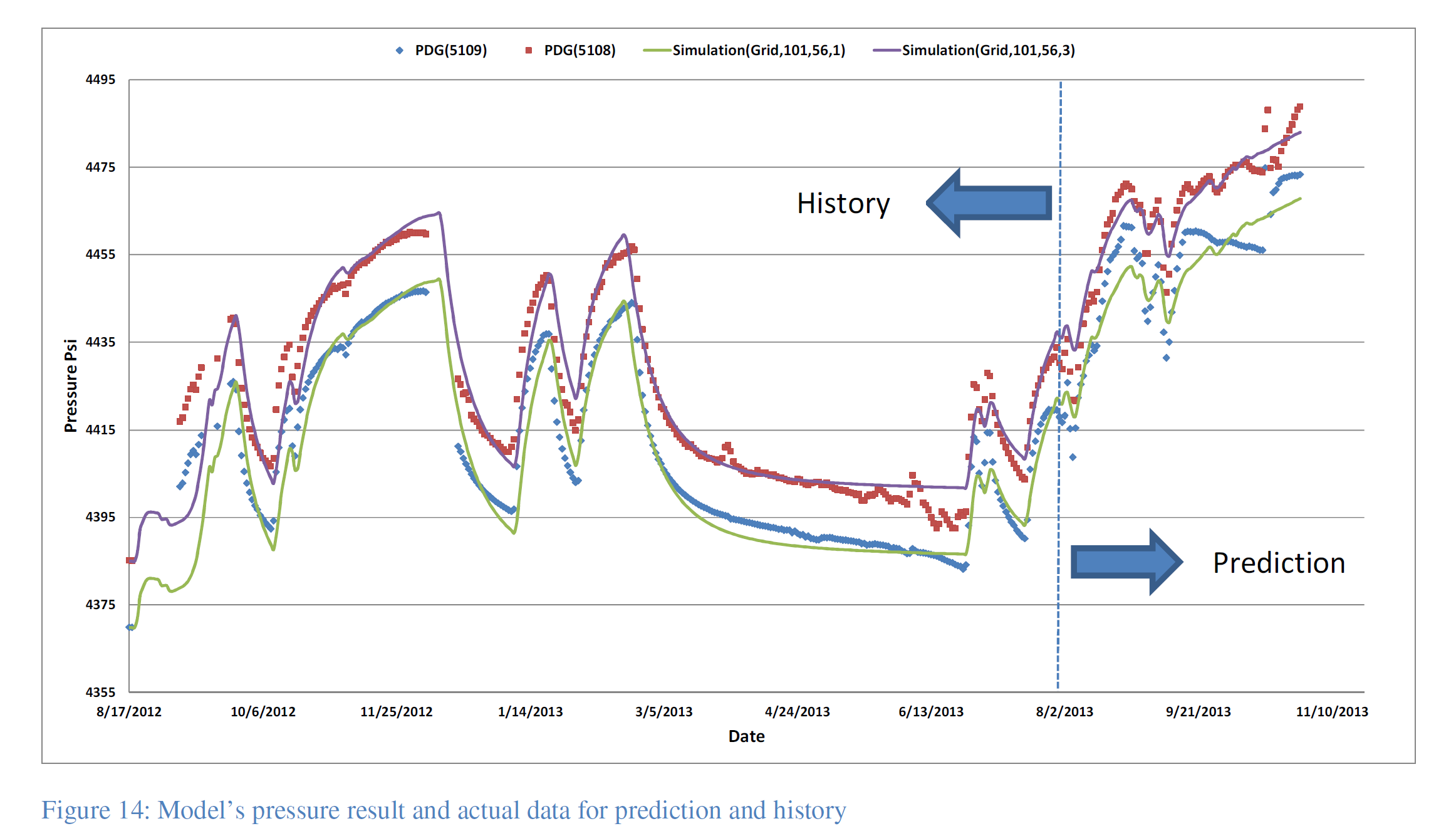

除了注入速率外,还提供了从一个观测井(距离注入井833英尺)嵌入的两个地下压力计的高频、实时压力数据。调整了几个不确定的储层属性在合理范围内,以找到模拟压力结果与实际现场测量结果之间的适当拟合。

Carbon Capture and Storage (CCS) projects are subject to monitoring and verification programs to insure the storage is operating safely. Among different verification techniques, Reservoir Simulation and Modeling has proved to be a powerful tool for predicting underground storage behavior and consequently quantifying the risks associated with CO2 storage process. Reliability of the reservoir simulation models is highly dependent on how accurately simulation results can represent the actual field measurements. This article presents a workflow aimed at history matching a reservoir simulation model for a CO 2 storage project. In this study a saline reservoir which is located in Citronelle Dome at Mobile County (Alabama, US) is considered for history matching. This project is part of a CO 2 storage research plan, conducted by the U.S. Department of Energy (DOE) and some industrial partners to demonstrate viability of commercial-scale storage of CO 2 captured from an existing coal-fired power plant. A Reservoir Simulation model for CO2 injection into the Citronelle saline aquifer was built using commercially available software (CMG-GEM). Field measurements of CO2 injection rates are assigned as the operational constraint to the model. In addition to the Injection rates, high frequency, real-time pressure data from two downhole pressure gauges imbedded in an observation well (833 ft. away from the injection well) is also provided. Several uncertain reservoir properties were tuned within reasonable ranges in order to find proper match between simulated pressure results and actual field measurements.