Production optimization of heavy oil recovery utilizing Mo-Ni based liquid catalysts: A simulation approach

重油的开采面临着高粘度和低流动性的重大挑战。因此,开发了多种方法来提高重油的采收率方式,包括催化剂的使用。本研究创建了一种独特的模拟方法,利用液体催化剂(LC)来提高重油采收率。通过实验室测试数据集和数值模拟研究,探讨了将LC作为替代化学剂应用于重油开采的潜力。使用CMG-STARS和CMOST模块对两次岩心驱替实验(水驱和液体催化剂驱替)进行历史拟合。此外,进行了敏感性研究,以确定最有效的过程控制参数。结果表明,与典型的水驱相比,注入LC时重油采收率显著提高,优化的生产方案可使最终油采收率提高至45.06%。注入速率、液体催化剂的体积和注入温度被发现是优化重油生产的重要因素。

CMG软件的应用情况

在本研究中,使用CMG-STARS进行重油开采的数值模拟,并结合CMOST模块进行历史拟合,以校准实验室结果并预测油藏的表现。这种方法能够有效地模拟实验室和现场的结果,为重油开采提供了可靠的技术支持。

Abstract

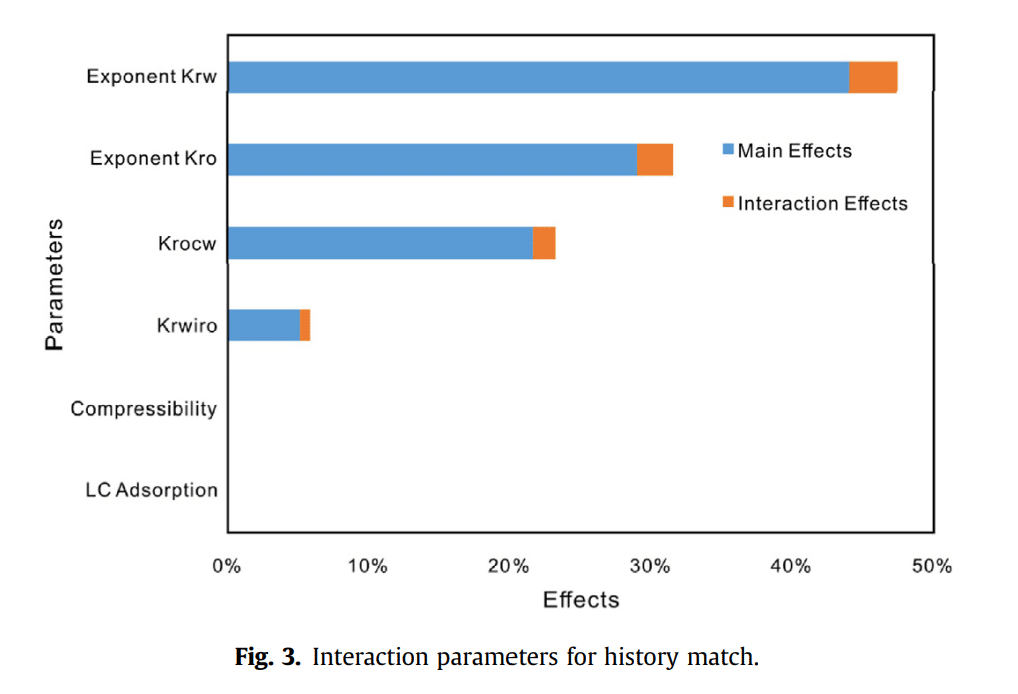

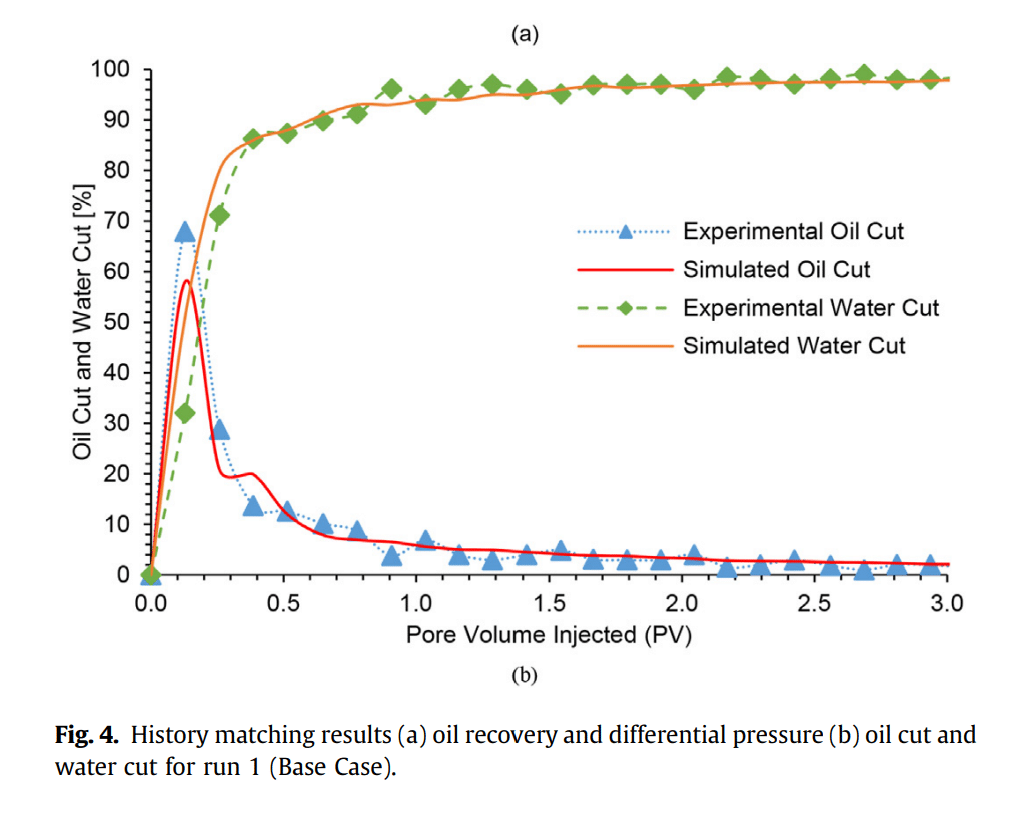

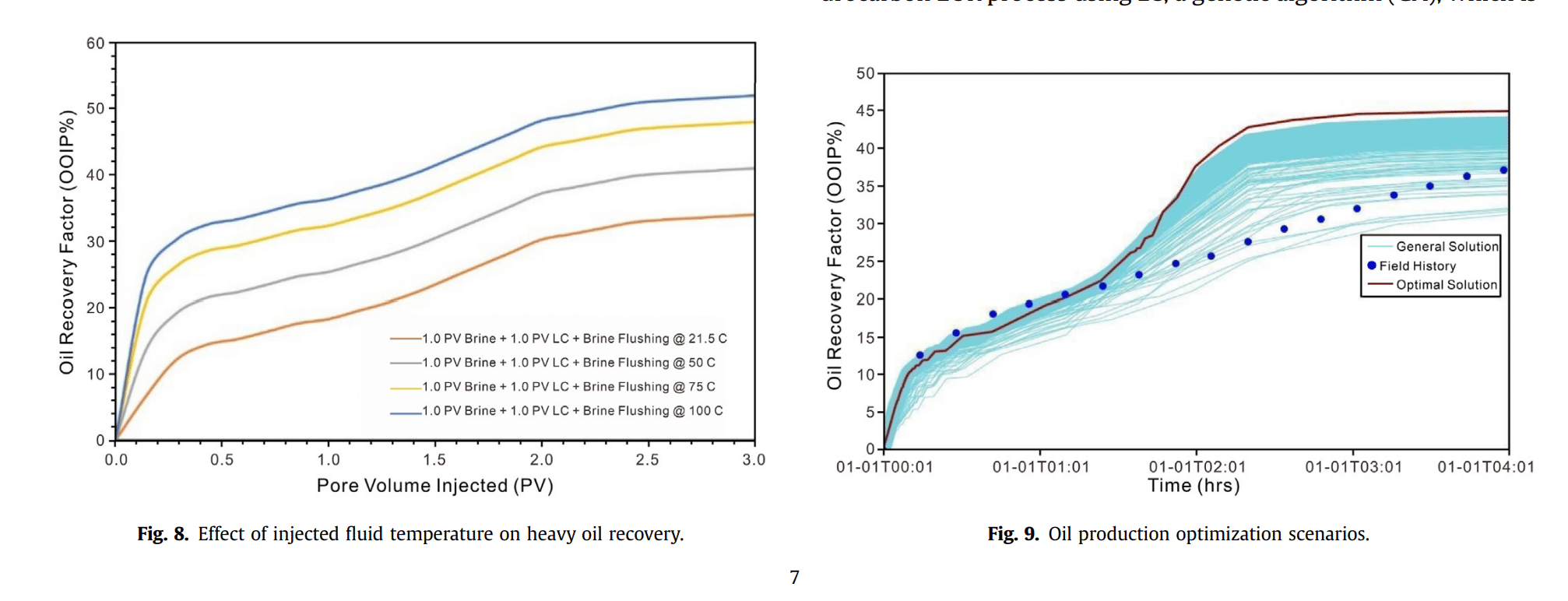

In recent years, the demand for heavy oil has increased due to its abundant availability and low cost. However, the extraction of heavy oil poses a significant challenge due to its high viscosity and low mobility. Therefore, various methods have been developed to enhance the recovery of heavy oil, including the use of catalysts. This study has created a unique simulation approach that uses liquid catalysts (LCs) to improve heavy oil recovery. In this work, laboratory testing dataset and numerical simulation studies were used to examine the potential of applying LCs as an alternative chemical agent for enhancing heavy oil recovery. CMG-STARS and CMOST modules were used to historical match the laboratory scale results of two sand-pack flooding experiments (water flooding and liquid catalyst flooding in tertiary recovery mode). Moreover, a sensitivity study was conducted to apply a wide range of assumptions to determine the most effective process controlling parameters. Finally, oil production optimization is performed using a genetic algorithm (particle swarm optimization) by selecting the optimum-operating parameters. In comparison to typical water flooding, the results revealed a discernible rise in the heavy oil recovery factor (RF) when injecting LCs. The simulation results showed that the optimized production strategy could increase the ultimate oil recovery by up to 45.06%. The injection rate, slug size, and injection temperature were found to be significant factors in optimizing the production of heavy oil. This simulation approach can be used to optimize the production of heavy oil using acidic Mo-Ni based liquid catalyst in different reservoirs.

Keywords

Liquid catalyst、Sensitivity analysis、History matching、Production optimization、Reservoir simulation

作者单位

加拿大里贾纳大学工程与应用科学学院