IN-SITU THERMAL DESTRUCTION (ISTD) OF MGP WASTE IN A FORMER GASHOLDER: DESIGN AND INSTALLATION

本文介绍了在马萨诸塞州一个前制造煤气厂(MGP)场地中,使用原位热解吸(ISTD)技术来修复含有残余煤焦油的气囊(GASHOLDER)。气囊最终被土壤和碎片回填,其墙壁和基础保持完好,封闭了一个约2013立方米的体积。基于气囊内有限的土壤调查,残余煤焦油遍布土壤中,底部1.2米深的土壤被煤焦油DNAPL饱和。ISTD技术被用来逐步修复气囊,以达到马萨诸塞州保护人类健康和地下水的土壤清洁标准,特别是针对多环芳烃(PAHs)、苯、石油烃和其他化合物。实验室对焦油样本的结果显示,温度仅升高56°C(100°F),焦油的粘度就会降低20倍。因此,提高土壤温度将增加焦油的流动性和可回收性。最初,加热器将在低温下运行,在此过程中,水和可回收焦油将通过两个液体提取井从气囊中产出。一旦水和可回收焦油被产出,加热器将被提升到全操作温度,土壤将被加热到至少325°C的最低目标温度。加热器井附近的土壤将过热,这将导致土壤中有机化合物的大量原位破坏。为了防止焦炭在加热器-真空(H-V)井附近形成并阻碍地下蒸汽流动,将在热井周围注入空气。

CMG软件应用情况:

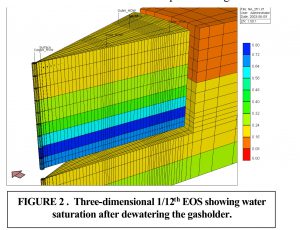

在该项目中,使用了STARS模拟器。STARS是一个三维、多相和多组分模型,考虑了组成、渗透率、毛管压力和所有流体及固体组分的反应。模型中包含了ISTD过程中可能发生的许多破坏反应,分为四大类:氧化、蒸汽重整、焦化和水煤气反应。模型结合了每种反应类别的文献动力学值,例如,在H-V井附近,B(a)P在1100°F(590°C)下的半衰期范围为氧化、蒸汽、焦化和水煤气反应的7至30秒。

作者单位:

- Terratherm, Inc., 马萨诸塞州,美国

- MK Tech Solutions, Inc. (MKTS), 德克萨斯州,美国

- National Grid USA, 西鲍罗,马萨诸塞州,美国

ABSTRACT:

In Situ Thermal Desorption (ISTD), also known as In-Situ Thermal Destruction, is being used to remediate a gasholder containing residual coal tar at a former manufactured gas plant (MGP) site in Massachusetts. When the gasholder was decommissioned, it was backfilled with soil and debris. The walls and base of the holder are intact, enclosing a volume of approximately 2,013 cubic yards (CY) (1,539 m3).

Water was present at a depth of approximately 3 ft (0.9 m) below ground surface (bgs) within the gasholder. Based on limited soil investigations within the gasholder, residual coal tar was present throughout the soils and the bottom 4 ft (1.2 m) of soil was saturated with coal tar DNAPL. ISTD is being used to remediate the gasholder in a step-wise fashion to achieve Massachusetts soil cleanup standards that are protective of human health and groundwater, with respect to polycyclic aromatic hydrocarbons (PAHs), benzene, petroleum hydrocarbons and other compounds.

Laboratory results on a sample of the tar indicate that a modest, 100°F (56°C) increase in temperature results in a 20-fold decrease in viscosity. Thus, raising the soil temperatures will increase the fluidity and recoverability of the tar. Initially the heaters will operate at low temperatures, during which water and recoverable tar will be removed from the gasholder via two liquid extraction wells. Once the water and recoverable tar have been removed, the heaters will be ramped up to their full operating temperature and the soil will be heated to a minimum target temperature of 617°F (325°C). Soil in close proximity to the heater wells will become superheated, which will result in substantial insitu destruction of the organic compounds. Air will be injected around the thermal wells to prevent coke from forming close to heater-vacuum (H-V) wells and obstructing subsurface vapor flow.