Heavy oil recovery by combined solvent and hot water (CS-HW) injection: Experimental, numerical and data mining-based analysis

本文开发了一种提高重油采收率(EHOR)的混合方法,将不同溶剂(如二氧化碳、甲烷和丙烷)与适度储层加热的热水混合注入。通过实验室实验(包括水驱、热水注入和溶剂注入)以及数值模拟,研究了这一混合注入技术对重油采收的影响。研究了注入速度、注入温度、溶剂类型和半周期注入量等因素对重油采收效率的影响。

实验结果表明,与单一注入方法相比,溶剂和热水注入联合工艺通过维持泡沫油流并有效延迟水和气突破时间,显著提高了重油采收率。此外,还开发了一种基于人工神经网络(ANN)的高性能神经模拟工具,用于预测联合溶剂和热水注入工艺的效率。

CMG软件应用情况

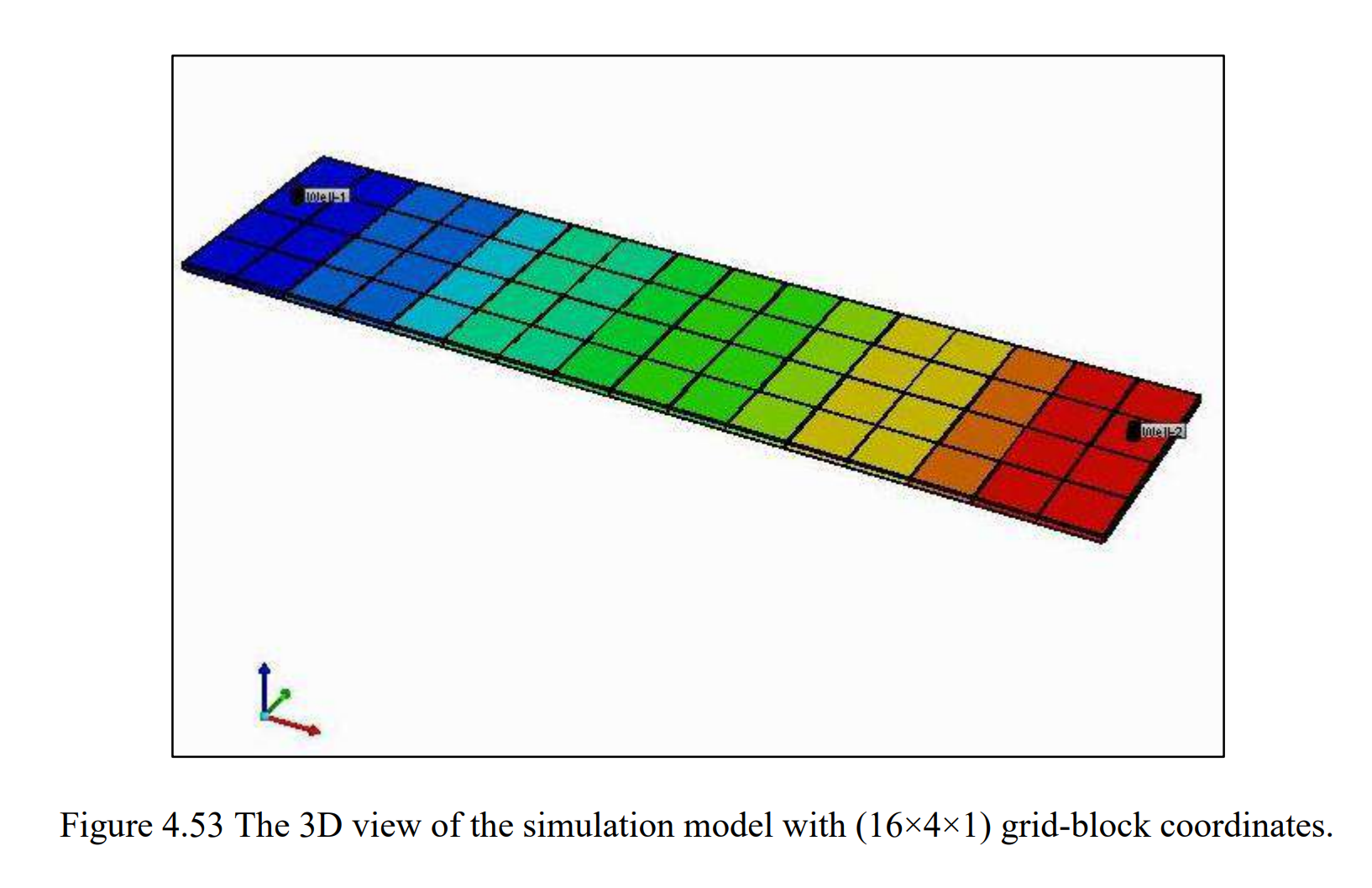

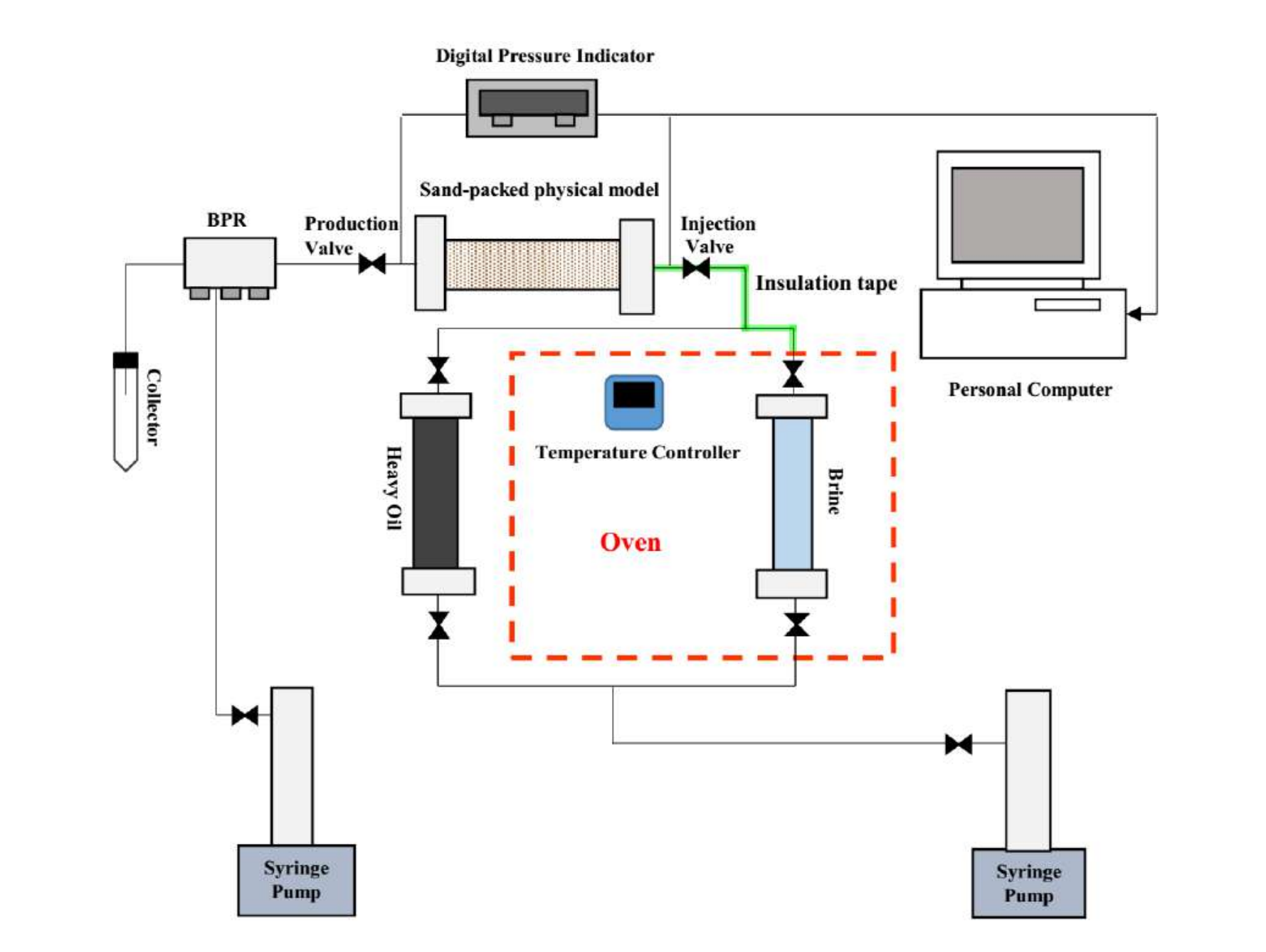

本文使用CMG-STARS模块进行数值模拟,模拟了不同注入场景下的重油采收情况。通过调整Peng-Robinson状态方程和EoS参数,使流体相态与实验数据拟合。模拟了水驱、热水注入、溶剂注入以及联合溶剂和热水注入等不同工艺,分析了注入速度、温度、溶剂类型等因素对采收率的影响。同时,使用CMG-Winprop模块创建了重油样本的PVT模型,以准确模拟实验室条件下的流体相态。

结论

- 注入速度对热水注入工艺的采收率有显著影响,0.75 PV/hr的注入速度在实验中取得了最高的采收率。

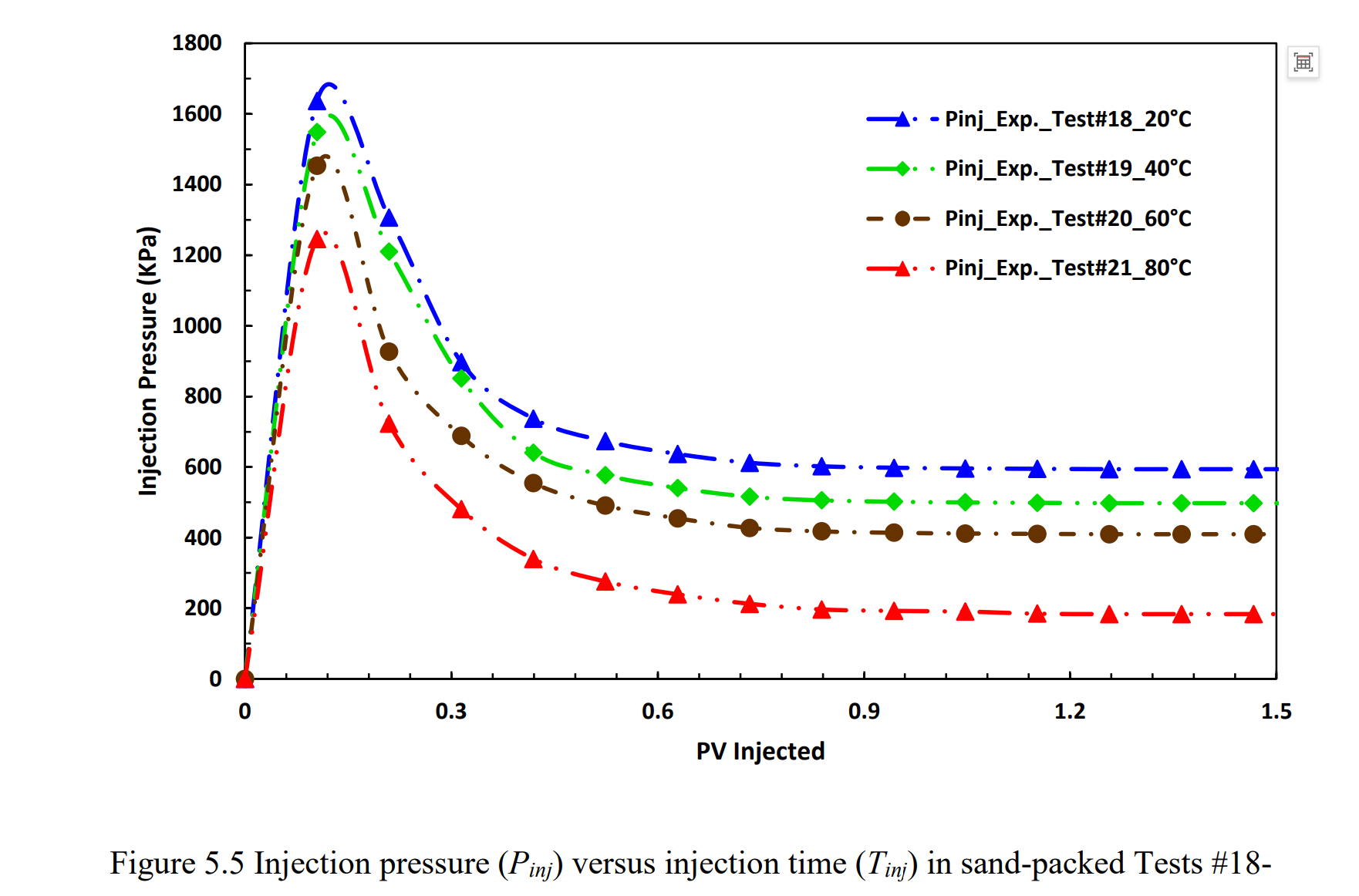

- 随着注入温度从20°C升高到80°C,重油采收率显著增加,但在80°C到100°C之间增幅较小。

- 丙烷(C3H8)注入在溶剂注入实验中取得了最高的采收率,因其在原油中的溶解度较高,能显著降低重油粘度。

- 半周期注入量(HCSS)对联合溶剂和热水注入工艺的效率有重要影响,较小的注入量(如0.25 PV)能提高采收率。

- 开发的计算方法和人工神经网络模型能够准确预测热水注入和联合溶剂热水注入工艺的性能,为实际生产提供了高效的预测工具。

作者单位

加拿大里贾纳大学石油系统工程系

Abstract

In this study, a hybrid EOR process is developed and optimized in a two-well configuration for heavy-oil recovery which combines solvent injection using different solvents such as carbon dioxide (CO2), methane (CH4) and propane (C3H8) with a moderate reservoir heating by hot-water flooding (HWF) as a solution to enhanced heavy oil recovery (EHOR), reduce energy consumption, and improved solvent retrieval efficiency. The combined injection of solvent and hot water offers several advantages including reduction of energy consumption compared to steam-based thermal EOR methods, and reduction of solvent volume required to reduce the viscosity of heavy oil. The proposed hybrid EOR method of combined solvent and hot water (CS-HW) injection outperformed the sole injection of solvent, conventional water flooding (WF) and hot-water flooding (HWF) by sustaining the foamy oil flow and effectively delaying water and gas breakthrough times. A total of 21 laboratory tests including water flooding (WF), hot-water flooding (HWF), solvent injection, combined solvent and hot water (CS-HW) injection in a two-well configuration were designed and conducted. More specifically, the design parameters such as injection rate (qinj) and temperature (Tinj), solvent composition and slug size were optimized with the objective of maximizing heavy oil recovery. In order to study the numerical simulation of CS-HW injection and other laboratory tests presented in this research, CMG-STARS module was used. Sensitivity analysis was performed on the effective parameters of CS-HW injection process to obtain the best history-match between the experimental data and the simulation model. Furthermore, a new computational approach for predicting the performance of hot-water flooding (HWF) in unconsolidated heavy oil reservoirs was presented. The proposed model predicts the changes in the oil–water viscosity ratio (μo/μw) by estimating the reservoir temperature distribution through porous media. Then, the dimensionless and normalized variables were redefined to forecast water fractional flow as a function of temperature and water saturation. Moreover, the proposed approach predicts the cumulative heavy oil production and recovery factor more accurately and with less required input data and runtime compared to CMG-STARS (computer modeling group), etc. Estimated results were validated using laboratory experimental data and numerical simulation outputs. The relative errors between oil recovery factors obtained from computational approach and experimental data were measured to be about 5.3%, 1.7% and 1.2% and 2.5% for injection temperatures of 40, 60, 80 and 100 °C, respectively. Finally, this thesis provides a novel data mining-based analysis by using artificial neural network (ANN) methodology to develop a high-performance neural simulation tool for predicting the efficiency of CS-HW injection process. In order to train, test and validate the model the experimental and simulation data obtained in this study together with available data in the literature were fed to the machine learning technique to develop a CSHW recovery performance predictive model. The proposed intelligent predictive model is expected to help petroleum engineers as an alternative model to predict the efficiency of CS-HW injection process, where other models have limitations and their input parameters are often not easily accessible.